Pro-Werks Butterfly Steering installed on new steering Shaft. Old tapered shaft preserved for uses idf desired.

Pro-Werks Butterfly Steering installed on new steering Shaft. Old tapered shaft preserved for uses idf desired. New set-up should provide more cockpit space

New set-up should provide more cockpit space A switch panel is planned to support warning lights.

A switch panel is planned to support warning lights.

Color matched gelcoat repair of sponsons has been completed.

Color matched gelcoat repair of sponsons has been completed. 4 layers or new glass was added to the full runner serface before gelcoat was applied. New trailer bunks can be seen in the background.

4 layers or new glass was added to the full runner serface before gelcoat was applied. New trailer bunks can be seen in the background. Replacement skid fin/air traps have been installed.

Replacement skid fin/air traps have been installed. Much care was given to not damage painted surfaces.

Much care was given to not damage painted surfaces. Custom fabricated trailer bow ring retainer has been installed.

Custom fabricated trailer bow ring retainer has been installed. Quick Release Steering wheel hub has been installed but may be replaced by Pro-Werks Butterfly wheel and Quick Release.

Quick Release Steering wheel hub has been installed but may be replaced by Pro-Werks Butterfly wheel and Quick Release. Parachute anchor has been fitted and will soon be fastened to transom. Holes will have to be drilled which violates the prime directive. OUCH!

Parachute anchor has been fitted and will soon be fastened to transom. Holes will have to be drilled which violates the prime directive. OUCH! Bottom portion of bracket has been replaced with custom piece to provide proper clearances.

Bottom portion of bracket has been replaced with custom piece to provide proper clearances. Chute anchor will also serve as tie down point.

Chute anchor will also serve as tie down point.

New Crane Roller Rockers, Jomar Stud Girdles.

New Crane Roller Rockers, Jomar Stud Girdles. Jomar NoBypass oil filter

Jomar NoBypass oil filter Pro-Werks C52-220 4 BOLT QUICK RELEASE STEERING HUB (SFI Certified)

Pro-Werks C52-220 4 BOLT QUICK RELEASE STEERING HUB (SFI Certified) Pro-Werks C42-484 BUTTERFLY STEERING WHEEL

Pro-Werks C42-484 BUTTERFLY STEERING WHEEL

New MSD 6462 6-BTM Boost Timing Master. Includes rev limiter and adjustable boost/timing in preperation for planned 6-71 blower.

New MSD 6462 6-BTM Boost Timing Master. Includes rev limiter and adjustable boost/timing in preperation for planned 6-71 blower. Changes to mounting hardware was required for new MSD unit.

Changes to mounting hardware was required for new MSD unit. Parachute restraint bracket will also double as tie-down point.

Parachute restraint bracket will also double as tie-down point. Custom bottom bracket will resolve clearance issue with water pickup.

Custom bottom bracket will resolve clearance issue with water pickup.

I finally pulled the trigger on a set of heads.

I finally pulled the trigger on a set of heads. Ford Performance Parts M-6049-SCJ

Ford Performance Parts M-6049-SCJ These new heads use the same 2.200-inch intake/1.76-inch exhaust valves, valvesprings, retainers, and standard 7/16-inch stud-mounted roller rockers as the current heads.

These new heads use the same 2.200-inch intake/1.76-inch exhaust valves, valvesprings, retainers, and standard 7/16-inch stud-mounted roller rockers as the current heads. New intake valve notches will be cut in pistons as needed.

New intake valve notches will be cut in pistons as needed.

Add Jomar Stud Girdles and we should have the top end covered

Add Jomar Stud Girdles and we should have the top end covered

Replacement skid fins have been fabricated due to trailer rub damage.

Replacement skid fins have been fabricated due to trailer rub damage. No damage on port side but a matched pair was the goal.

No damage on port side but a matched pair was the goal.

Twisted Propeller shaft. See left most portion of keyway.

Twisted Propeller shaft. See left most portion of keyway. I haven't had the boat in the water yet so the damage was done some time ago.

I haven't had the boat in the water yet so the damage was done some time ago. I would not have expected this engine to be capable of twisting the shaft like this.

I would not have expected this engine to be capable of twisting the shaft like this.

Time to do some work on the trailer and re-gelcoat the sponsons (Color Matched)

Time to do some work on the trailer and re-gelcoat the sponsons (Color Matched) Trailer bunks were raised with boat to avoid damage to boat.

Trailer bunks were raised with boat to avoid damage to boat. Brownell Boat stands. I beams to facilitate ease of trailer removal (wheels off).

Brownell Boat stands. I beams to facilitate ease of trailer removal (wheels off). New bunks are being installed on the trailer due to complexity of installing carrige bolts on old bunks.

New bunks are being installed on the trailer due to complexity of installing carrige bolts on old bunks.

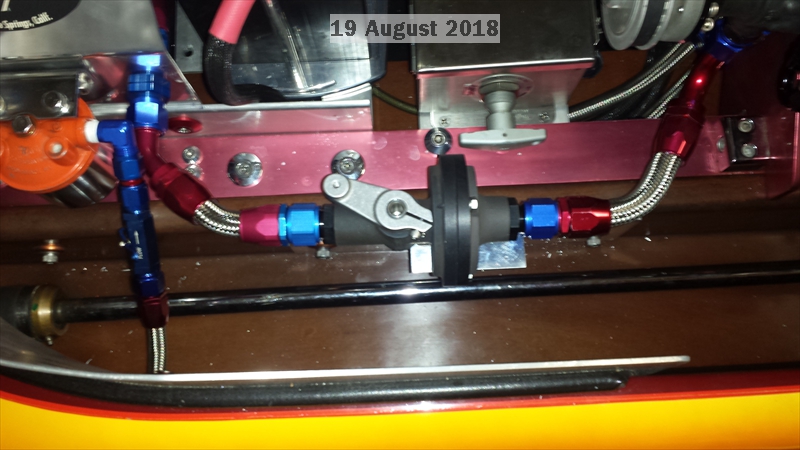

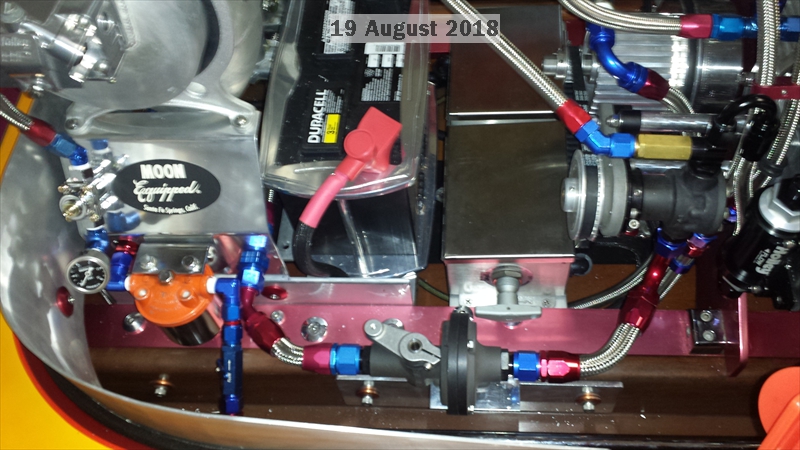

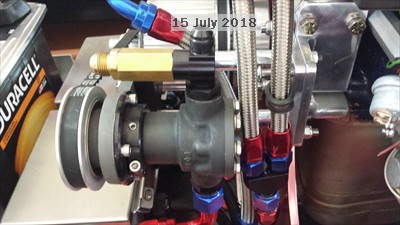

All fuel system components installed except line from final filter to fuel rail.

All fuel system components installed except line from final filter to fuel rail. Enderle pre pump filter and shut-off.

Enderle pre pump filter and shut-off. Holley final filter between pump and fuel rail.

Holley final filter between pump and fuel rail. Starboard side shutoff and filter for saddle tank plus regulator and gauge between electric fuel pump and Moon tank.

Starboard side shutoff and filter for saddle tank plus regulator and gauge between electric fuel pump and Moon tank.

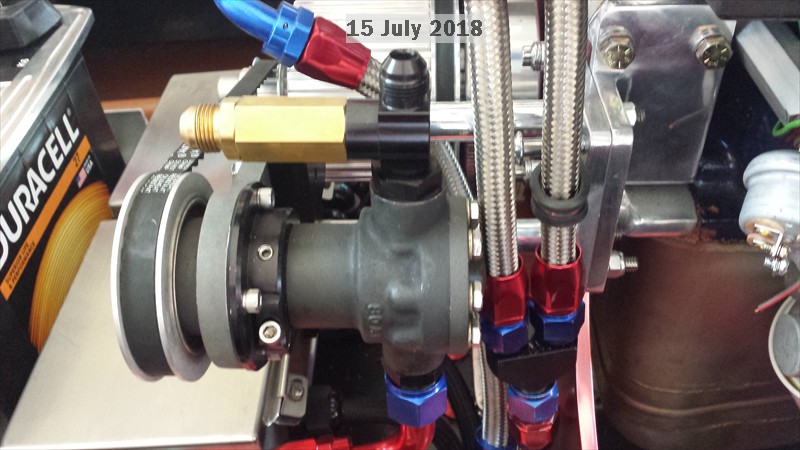

Enderle Pump with custom bracket completed.

Enderle Pump with custom bracket completed. Enderle 6-PSI bypass valve.

Enderle 6-PSI bypass valve. Pending installation of fuel filter and lines.

Pending installation of fuel filter and lines. New Holley Fuel Bowl installed on Moon tank.

New Holley Fuel Bowl installed on Moon tank. Just need to finalize placement of remaining fuel system components. More complicated than one would think.

Just need to finalize placement of remaining fuel system components. More complicated than one would think.

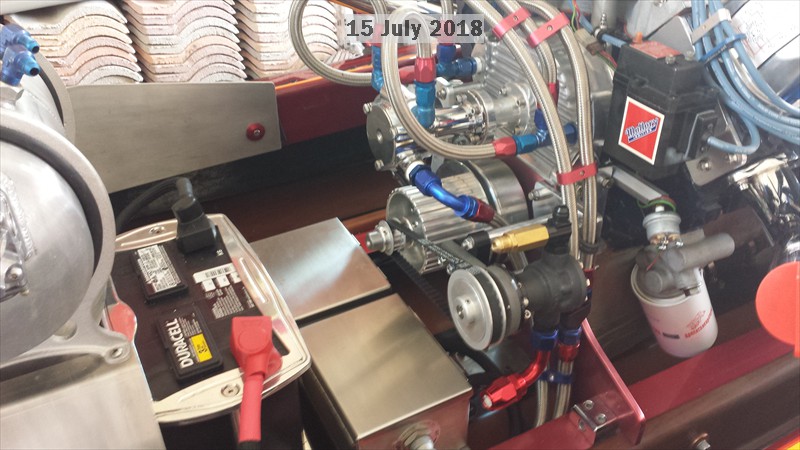

Moon "T' tank has been installed in support of future mechanical fuel Injection (Blower with Hat).

Moon "T' tank has been installed in support of future mechanical fuel Injection (Blower with Hat). Enderle Crank Mandrel will be used to drive the 80a-1 fuel pump.

Enderle Crank Mandrel will be used to drive the 80a-1 fuel pump. Installation of fuel lines and supporting fuel components is pending.

Installation of fuel lines and supporting fuel components is pending. Moon tank has factory integrated Holley Fuel bowl to regulate fuel level in tank.

Moon tank has factory integrated Holley Fuel bowl to regulate fuel level in tank.

Bassett zoomies arrived and are installed.

Bassett zoomies arrived and are installed.

Clearance between deck and headers seems good to avoid heat related paint damage

Clearance between deck and headers seems good to avoid heat related paint damage Dust covers in place.

Dust covers in place.

Bassett scoop replaces velocity stacks. Russell Valve cover T-Bar Bolts replace Arps 12 point for easy access to valve train. New brackets were fabricated to hold engine related support devices. MSD moves from stringer to new engine bracket. Vented puke tank was installed in support of upcoming Blower installation. Bassett headers will be coming off later this week when Bassett chrome zoomies arrive.

Bassett scoop replaces velocity stacks. Russell Valve cover T-Bar Bolts replace Arps 12 point for easy access to valve train. New brackets were fabricated to hold engine related support devices. MSD moves from stringer to new engine bracket. Vented puke tank was installed in support of upcoming Blower installation. Bassett headers will be coming off later this week when Bassett chrome zoomies arrive.  Engine electrical box has been upgraded to twice the size and has drop down hinged door. Throttle bracket and new cable are now installed and are consistent with future blower. Fuel manifold and lines are also now consistent with future direction. Unseen are the new stringer brackets to hold electrical and braided fuel and water lines. Also unseen is the new wiring and tag bracket for the trailer as well as new aluminum trailer bunk brackets.

Engine electrical box has been upgraded to twice the size and has drop down hinged door. Throttle bracket and new cable are now installed and are consistent with future blower. Fuel manifold and lines are also now consistent with future direction. Unseen are the new stringer brackets to hold electrical and braided fuel and water lines. Also unseen is the new wiring and tag bracket for the trailer as well as new aluminum trailer bunk brackets.

Linkage and fuel lines changed to establish consistancy with Tunnel Ram setup.

Linkage and fuel lines changed to establish consistancy with Tunnel Ram setup.

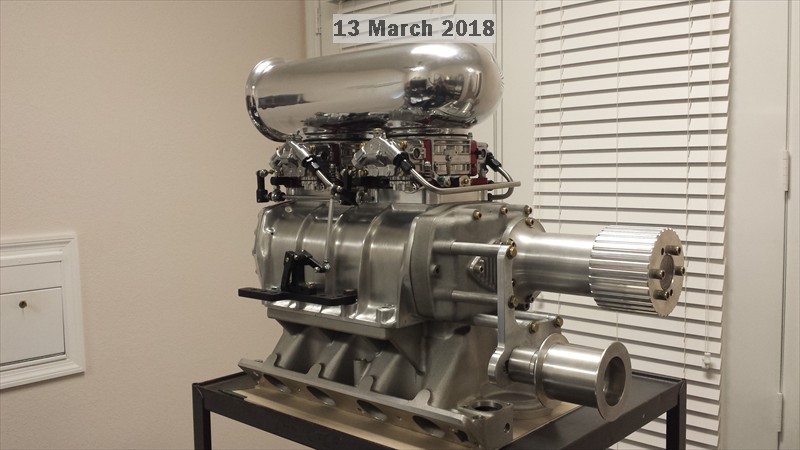

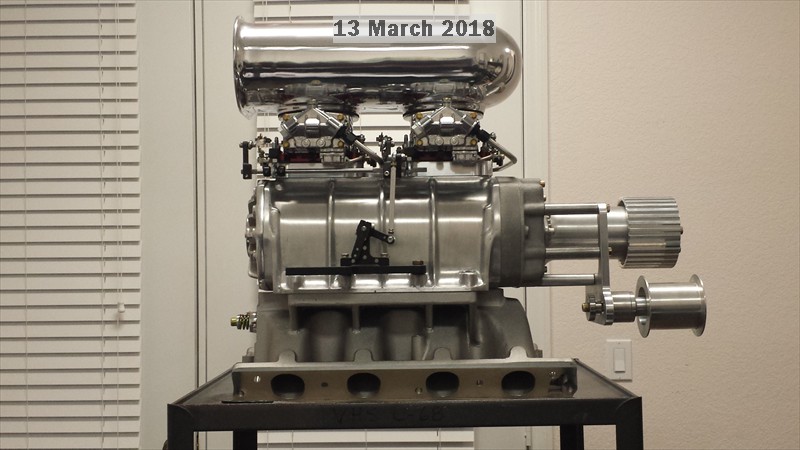

Blower case polished.

Blower case polished. Plan is to run the boat with tunnel ram setup to establish a baseline before installing blower.

Plan is to run the boat with tunnel ram setup to establish a baseline before installing blower.

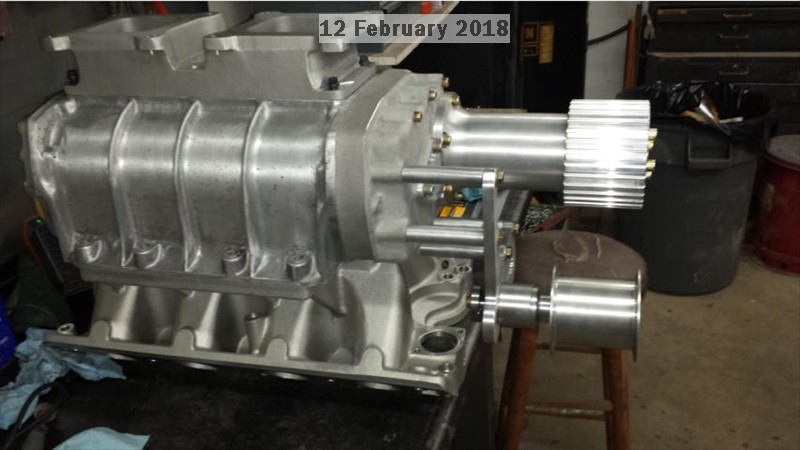

Blower casting sanded to brushed finish.

Blower casting sanded to brushed finish.

Quick Fuel Carburetors in place.

Quick Fuel Carburetors in place. Enderle Linkage operational

Enderle Linkage operational

Blower Idler pulley brackets are now complete.

Blower Idler pulley brackets are now complete.

New Harmonic Damper to support the 6 hole Blower style Pulleys. Original Moroso alternator pulley was reinstalled since the pulley spacing now works out and this pulley is desired because of the high engine RPM.

New Harmonic Damper to support the 6 hole Blower style Pulleys. Original Moroso alternator pulley was reinstalled since the pulley spacing now works out and this pulley is desired because of the high engine RPM.

Some say I’ve gone mad. I don’t really see a problem

Some say I’ve gone mad. I don’t really see a problem Really ...........

Really ...........

Evolution 2018

Pro-Werks Butterfly Steering installed on new steering Shaft. Old tapered shaft preserved for uses idf desired.

Pro-Werks Butterfly Steering installed on new steering Shaft. Old tapered shaft preserved for uses idf desired. New set-up should provide more cockpit space

New set-up should provide more cockpit space A switch panel is planned to support warning lights.

A switch panel is planned to support warning lights.

Color matched gelcoat repair of sponsons has been completed.

Color matched gelcoat repair of sponsons has been completed. 4 layers or new glass was added to the full runner serface before gelcoat was applied. New trailer bunks can be seen in the background.

4 layers or new glass was added to the full runner serface before gelcoat was applied. New trailer bunks can be seen in the background. Replacement skid fin/air traps have been installed.

Replacement skid fin/air traps have been installed. Much care was given to not damage painted surfaces.

Much care was given to not damage painted surfaces. Custom fabricated trailer bow ring retainer has been installed.

Custom fabricated trailer bow ring retainer has been installed. Quick Release Steering wheel hub has been installed but may be replaced by Pro-Werks Butterfly wheel and Quick Release.

Quick Release Steering wheel hub has been installed but may be replaced by Pro-Werks Butterfly wheel and Quick Release. Parachute anchor has been fitted and will soon be fastened to transom. Holes will have to be drilled which violates the prime directive. OUCH!

Parachute anchor has been fitted and will soon be fastened to transom. Holes will have to be drilled which violates the prime directive. OUCH! Bottom portion of bracket has been replaced with custom piece to provide proper clearances.

Bottom portion of bracket has been replaced with custom piece to provide proper clearances. Chute anchor will also serve as tie down point.

Chute anchor will also serve as tie down point.

New Crane Roller Rockers, Jomar Stud Girdles.

New Crane Roller Rockers, Jomar Stud Girdles. Jomar NoBypass oil filter.

Jomar NoBypass oil filter. Pro-Werks C42-484 BUTTERFLY STEERING WHEEL

Pro-Werks C42-484 BUTTERFLY STEERING WHEEL New Crane Roller Rockers, Jomar Stud Girdles.

New Crane Roller Rockers, Jomar Stud Girdles.

New MSD 6462 6-BTM Boost Timing Master. Includes rev limiter and adjustable boost/timing in preperation for planned 6-71 blower.

New MSD 6462 6-BTM Boost Timing Master. Includes rev limiter and adjustable boost/timing in preperation for planned 6-71 blower. Changes to mounting hardware was required for new MSD unit.

Changes to mounting hardware was required for new MSD unit. Parachute restraint bracket will also double as tie-down point.

Parachute restraint bracket will also double as tie-down point. Custom bottom bracket will resolve clearance issue with water pickup.

Custom bottom bracket will resolve clearance issue with water pickup.

I finally pulled the trigger on a set of heads.

I finally pulled the trigger on a set of heads. Ford Performance Parts M-6049-SCJ

Ford Performance Parts M-6049-SCJ These new heads use the same 2.200-inch intake/1.76-inch exhaust valves, valvesprings, retainers, and standard 7/16-inch stud-mounted roller rockers as the current heads.

These new heads use the same 2.200-inch intake/1.76-inch exhaust valves, valvesprings, retainers, and standard 7/16-inch stud-mounted roller rockers as the current heads. New intake valve notches will be cut in pistons as needed.

New intake valve notches will be cut in pistons as needed.

Add Jomar Stud Girdles and we should have the top end covered

Add Jomar Stud Girdles and we should have the top end covered

Replacement skid fins have been fabricated due to trailer rub damage.

Replacement skid fins have been fabricated due to trailer rub damage. No damage on port side but a matched pair was the goal.

No damage on port side but a matched pair was the goal.

Twisted Propeller shaft. See left most portion of keyway.

Twisted Propeller shaft. See left most portion of keyway. I haven't had the boat in the water yet so the damage was done some time ago. I would not have expected this engine to be capable of twisting the shaft like this.

I haven't had the boat in the water yet so the damage was done some time ago. I would not have expected this engine to be capable of twisting the shaft like this. This shaft was replaced with an Aquamet 22 Stainless Steel 1" Propeller Shaft.

This shaft was replaced with an Aquamet 22 Stainless Steel 1" Propeller Shaft.

Time to do some work on the trailer and re-gelcoat the sponsons (Color Matched).

Time to do some work on the trailer and re-gelcoat the sponsons (Color Matched). Trailer bunks were raised with boat to avoid damage to boat.

Trailer bunks were raised with boat to avoid damage to boat. Brownell Boat stands. I-beams to facilitate ease of trailer removal (wheels off).

Brownell Boat stands. I-beams to facilitate ease of trailer removal (wheels off). New bunks are being installed on the trailer due to complexity of installing carrige bolts on old bunks.

New bunks are being installed on the trailer due to complexity of installing carrige bolts on old bunks.

All fuel system components installed except line from final filter to fuel rail.

All fuel system components installed except line from final filter to fuel rail. Enderle pre pump filter and shut-off.

Enderle pre pump filter and shut-off. Holley final filter between pump and fuel rail.

Holley final filter between pump and fuel rail. Starboard side shutoff and filter for saddle tank plus regulator and gauge between electric fuel pump and Moon tank.

Starboard side shutoff and filter for saddle tank plus regulator and gauge between electric fuel pump and Moon tank.

Enderle Pump with custom bracket completed.

Enderle Pump with custom bracket completed. Enderle 6-PSI bypass valve

Enderle 6-PSI bypass valve Pending installation of fuel filter and lines

Pending installation of fuel filter and lines New Holley Fuel Bowl installed on Moon tank

New Holley Fuel Bowl installed on Moon tank Just need to finalize placement of remaining fuel system components. More complicated than one would think.

Just need to finalize placement of remaining fuel system components. More complicated than one would think.

Moon "T' tank has been installed in support of future mechanical fuel Injection (Blower with Hat).

Moon "T' tank has been installed in support of future mechanical fuel Injection (Blower with Hat). Enderle Crank Mandrel will be used to drive the 80a-1 fuel pump.

Enderle Crank Mandrel will be used to drive the 80a-1 fuel pump. Installation of fuel lines and supporting fuel components is pending.

Installation of fuel lines and supporting fuel components is pending. Moon tank has factory integrated Holley Fuel bowl to regulate fuel level in tank.

Moon tank has factory integrated Holley Fuel bowl to regulate fuel level in tank.

Bassett zoomies arrived and are installed.

Bassett zoomies arrived and are installed.

Clearance between deck and headers seems good to avoid heat related paint damage

Clearance between deck and headers seems good to avoid heat related paint damage Dust covers in place.

Dust covers in place.

Bassett scoop replaces velocity stacks. Russell Valve cover T-Bar Bolts replace Arps 12 point for easy access to valve train. New brackets were fabricated to hold engine related support devices. MSD moves from stringer to new engine bracket. Vented puke tank was installed in support of upcoming Blower installation. Bassett headers will be coming off later this week when Bassett chrome zoomies arrive.

Bassett scoop replaces velocity stacks. Russell Valve cover T-Bar Bolts replace Arps 12 point for easy access to valve train. New brackets were fabricated to hold engine related support devices. MSD moves from stringer to new engine bracket. Vented puke tank was installed in support of upcoming Blower installation. Bassett headers will be coming off later this week when Bassett chrome zoomies arrive.  Engine electrical box has been upgraded to twice the size and has drop down hinged door. Throttle bracket and new cable are now installed and are consistent with future blower. Fuel manifold and lines are also now consistent with future direction. Unseen are the new stringer brackets to hold electrical and braided fuel and water lines. Also unseen is the new wiring and tag bracket for the trailer as well as new aluminum trailer bunk brackets.

Engine electrical box has been upgraded to twice the size and has drop down hinged door. Throttle bracket and new cable are now installed and are consistent with future blower. Fuel manifold and lines are also now consistent with future direction. Unseen are the new stringer brackets to hold electrical and braided fuel and water lines. Also unseen is the new wiring and tag bracket for the trailer as well as new aluminum trailer bunk brackets.

Linkage and fuel lines changed to establish consistancy with Tunnel Ram setup.

Linkage and fuel lines changed to establish consistancy with Tunnel Ram setup.

Blower case polished.

Blower case polished. Plan is to run the boat with tunnel ram setup to establish a baseline before installing blower.

Plan is to run the boat with tunnel ram setup to establish a baseline before installing blower.

Blower casting sanded to brushed finish.

Blower casting sanded to brushed finish.

Quick Fuel Carburetors in place.

Quick Fuel Carburetors in place. Enderle Linkage operational

Enderle Linkage operational

Blower Idler pulley brackets are now complete.

Blower Idler pulley brackets are now complete.

New Harmonic Damper to support the 6 hole Blower style Pulleys. Original Moroso alternator pulley was reinstalled since the pulley spacing now works out and this pulley is desired because of the high engine RPM.

New Harmonic Damper to support the 6 hole Blower style Pulleys. Original Moroso alternator pulley was reinstalled since the pulley spacing now works out and this pulley is desired because of the high engine RPM.

Some say I’ve gone mad. I don’t really see a problem

Some say I’ve gone mad. I don’t really see a problem Really ...........

Really ...........

Evolution 2018